Your health, your company — and silica dust

Why dust is such a serious health hazard, and what you can do about it.

BY FRANK BOURQUEDust is a reality for anyone in landscape construction. When you inhale dust from cutting or grinding concrete, mixing materials, dry sweeping or demolition, tiny quartz/silica particles penetrate deep into the lungs and cause scarring and disease.

The risks are so serious, regulations have been put in place for Canada by the Canadian Centre for Occupational Health and Safety (CCOHS) and for the U.S. by Occupational Safety and Health Administration (OSHA), to create awareness and manage this risk at worksites. The goal is to create safer work environments with reduced health risks for you, your employees and anyone exposed to construction dust.

Dry cutting with a dust shroud to contain the silica dust.

Dry cutting with a dust shroud to contain the silica dust.

Know the hazard

Crystalline silica is an extremely common mineral found in sand, stone, and concrete that becomes dangerous when disturbed. Cutting, crushing, grinding, or drilling of stone, brick or concrete generates a fine silica dust that, unless contained, will seriously contaminate the air. Inhaled silica dust causes fibrosis or scar tissue, as well as silicosis lung disease, both of which reduce the lungs’ ability to extract oxygen from the air. There is no cure for these often-fatal diseases.Know the standard

In Canada, the CCOHS is a great place to start for information. There are 14 jurisdictions that have their own Occupational Health and Safety legislation, including occupational silica exposure limits. You can find the exposure limits and links to the legislation for each province in the online version of this article at www.landscapetrades.com/silica.In Ontario, for example, the legislation does more than specify exposure limits. It also requires employers to take steps to protect employees from the hazard and defines employer responsibilities if exposure takes place

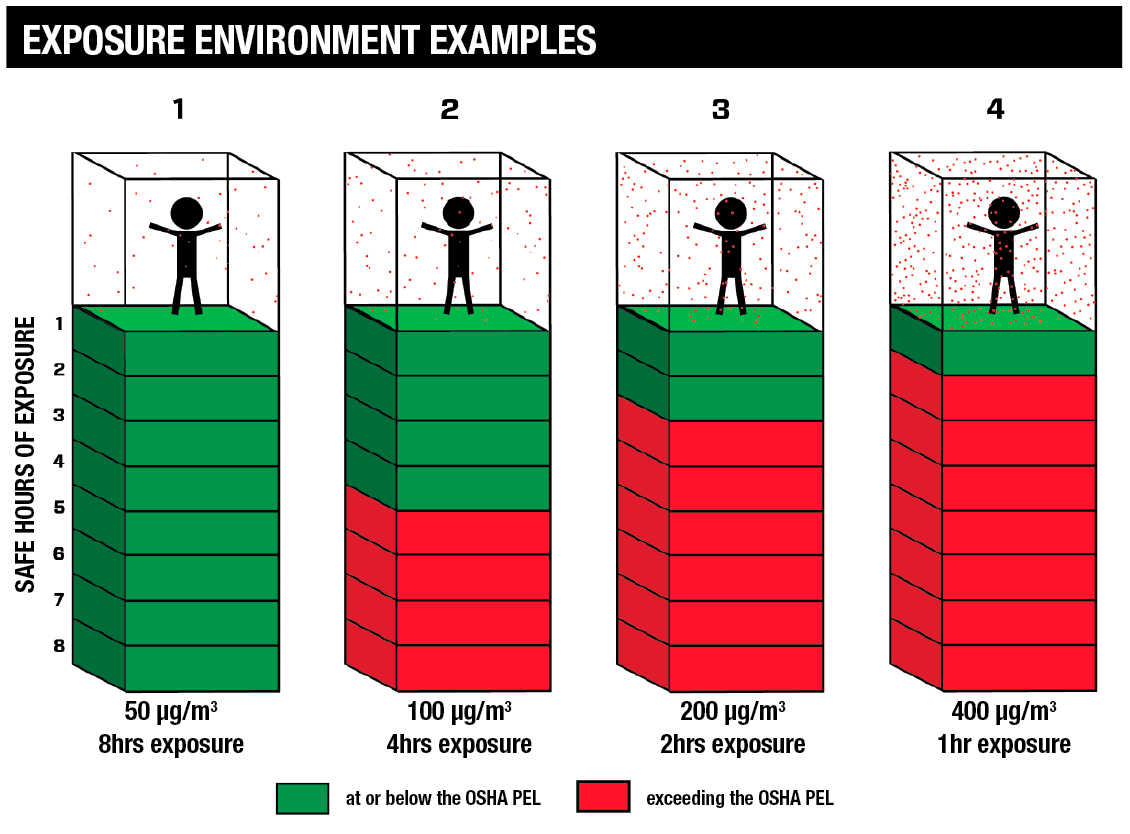

In the U.S., the OSHA Silica Standard, implemented in 2016, limits silica exposure to a Permissible Exposure Limit (PEL) of 50 micrograms of respirable crystalline silica per cubic metre of air or 50 µg SiO2/m³ over an eight-hour time weighted average (TWA). OSHA recognizes using tools equipped with a water delivery system that supplies a continuous stream or spray of water at the point of impact, or using tools equipped with a commercially available shroud and dust collection system, as control methods that safely limit silica exposure.

Cutting, grinding, or drilling of hardscape materials generates a fine silica dust that contaminates the air.

Cutting, grinding, or drilling of hardscape materials generates a fine silica dust that contaminates the air.

Generally, Canadian regulations are comparable to U.S. regulations. However, violations in the U.S. are expensive; fines of over $7,500 per person are given for breach of the Silica Regulation. With the importance given to the silica issue in the U.S., we are likely to see similar enforcement and fines in Canada in the near future.

Know your exposure

One way to determine silica exposure is through air monitoring. This may seem like a complicated, expensive process; however, it’s fairly easy once you understand what is involved.Air monitoring equipment measures the air quality in a worker’s breathing area to determine silica exposure during a specific work practice. Air monitoring uses a battery-operated vacuum attached to an operator’s shirt collar, collecting air samples right where the operator breathes. Once you learn your exposure levels, you can decide what options are best suited to control silica exposure on your job sites.

Another way to determine silica exposure is by using objective data provided by tool manufacturers. In the U.S., OSHA defines Objective Data as “information, such as air monitoring data, from industry-wide surveys or calculations based on the composition of a substance, demonstrating employee exposure to respirable crystalline silica associated with a particular product or material or a specific process, task, or activity. The data must reflect workplace conditions closely resembling or with a higher exposure potential than the processes, types of material, control methods, work practices, and environmental conditions in the employer’s current operations.” When a manufacturer tests its equipment, if the work practice and materials used match job site conditions, OSHA allows this data to be used as objective data as part of a written silica exposure control plan (https://plan.silica-safe.org).

Safe and hazardous occupational silica exposure levels.

Safe and hazardous occupational silica exposure levels.

The PEL requires employers to limit worker exposures to respirable crystalline silica and take other steps to protect employees. Regardless of exposure control methods used, you should implement a Silica Safety Program including the following elements:

- Hazard identification, assessment and solutions.

- Trained staff member for implementation and monitoring.

- Offer of medical exams.

- Documented training.

- Record keeping.

In my experience, the key to protecting yourself and your employees is to take responsibility and implement systems. Just because a tool is CCOHS Compliant, it does not automatically mean the company using the tool is compliant with the regulation.

Know your options

The construction industry and associated technologies are rapidly changing. Wet cutting and dry cutting without a vacuum have been the main applications for cutting concrete, asphalt and masonry materials for decades. Three main dust control strategies are available to today’s contractors:- Wet cutting.

- Dry cutting with a dust shroud.

- Dry cutting with integrated dust collection.

Wet cutting is a good choice when a cutting station is available, but can be a messy alternative without.

Wet cutting is a good choice when a cutting station is available, but can be a messy alternative without.

No matter what tool you’re using, it’s essential to wear personal protective equipment such as eyewear and ear attenuators. Know exactly what you’re cutting so you can implement proper control methods. Following a control hierarchy, listed below from most to least efficient, is the best way to control dust hazards:

- Elimination: Physically remove the hazard.

- Substitution: Replace the hazard.

- Engineering controls: Isolate people from the hazard.

- Administrative controls: Change the way people work.

- Personal protective equipment: Least efficient, but mandatory.

Silica summary

Know the hazard Understand the hazard and risks associated with silica exposure.Know the standard Understand the CCOHS Permissible Exposure Limit and what it means to you, your business and your workers.

Know your exposure Understand how to use air monitoring to measure silica exposure levels — and understand the results.

Know your options Understand your options, including tools, work practices and educational resources for controlling silica exposure on your job sites.

| Jurisdiction | Regulation | 8 Hour Exposure Limit |

| Federal | Canada Occupational Health and Safety Regulations | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| British Columbia | Occupational Health and Safety Regulation Part 5 Chemical Agents and Biological Agents |

Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| Alberta | Occupational Health and Safety Code 2009 Part 4 Chemical Hazards, Biological Hazards and Harmful Substances |

Cristabolite (respirable): 0.025 mg/m3 Quartz (respirable): 0.025 mg/m3 |

| Saskatchewan | The Occupational Health and Safety Regulations, 1996 |

Cristobalite (respirable): 0.05 mg/m3 Quartz (respirable fraction): 0.05 mg/m3 Tripoli, as quartz (respirable): 0.1 mg/m3 |

| Manitoba | Occupational Health and Safety Regulation | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| Ontario | Regulation 833: Control of Exposure to Biological or Chemical Agents | Quartz/Tripoli (respirable): 0.10 mg/m3 Cristobalite (respirable): 0.05 mg/m3 |

| Quebec | Regulation respecting occupational health and safety | Cristobalite: 0.05 mg/m3 Quartz: 0.1 mg/m3 Tridymite: 0.05 mg/m3 Tripoli: 0.1 mg/m3 |

| New Brunswick | General Regulation | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| Nova Scotia | Workplace Health and Safety Regulations | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| Newfoundland and Labrador | Occupational Health and Safety Regulations, 2012 | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| Prince Edward Island | General Regulations | Use ACGIH TLVs Quartz and Cristobalite (respirable): 0.025 mg/m3 |

| Northwest Territories | Occupational Health and Safety Regulations | Cristobalite (respirable): 0.05 mg/m3 Quartz (respirable): 0.05 mg/m3 Tripoli, as quartz: 0.1 mg/m3 |

| Nunavut | Consolidation of Occupational Health and Safety Regulations | Cristobalite (respirable) : 0.05 mg/m3 Quartz (respirable): 0.05 mg/m3 Tripoli, as quartz: 0.1 mg/m3 |

| Yukon | Occupational Health Regulation | Quartz: 300 particles/mL Cristobalite: 150 particles/mL Tridymite: 150 particles/mL |

Frank Bourque is a speaker, writer, consultant, entrepreneur and Interlocking Concrete Pavement Institute instructor who coaches hardscape pros across North America. Thanks to iQ Power Tools and Hulton Tool for photos and information used in this article.